Leading Manufacturers & Exporters of Electrical Insulation Materials

ELECRAMA 2025 was a grand stage for global innovators, manufacturers, and industry leaders in the electrical and power sector. The event was bigger than any previous edition, bringing together cutting-edge technology and future-ready solutions.

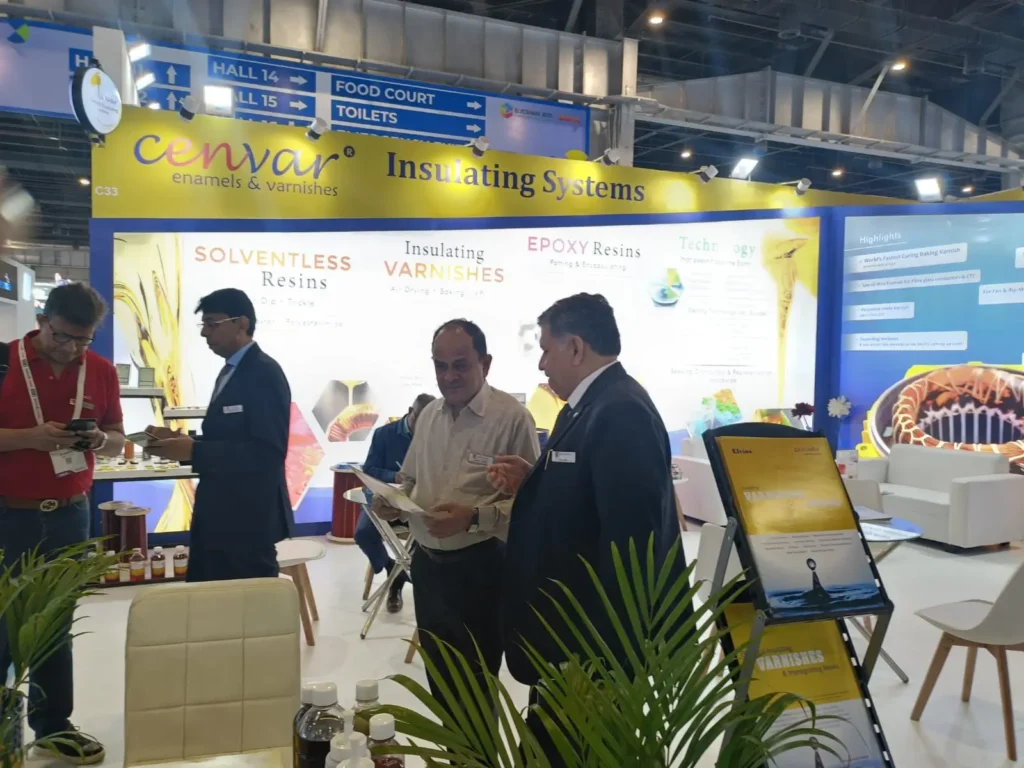

For Cenvar | Chetak Mfg, a leading manufacturer and exporter of insulating varnishes, enamelled copper and aluminium winding wires, impregnating resins, epoxy systems, and wire enamels, this event was yet another milestone in our legacy.

Since ELECRAMA 2006, we have showcased our complete portfolio of products, growing with each edition—2008, 2010, 2012, 2014, 2016, 2018, 2020, 2023, and now the largest ever, 2025.

What is ELECRAMA? The Global Hub for the Electrical Industry

ELECRAMA is the world’s largest showcase of the electrical, electronics, and power industry. Held every two years, it attracts manufacturers, exporters, buyers, and innovators from across the globe.

The ELECRAMA 2025 edition broke all records in terms of participation, technology showcases, and business opportunities. It was the epicenter for discussions on power infrastructure, energy efficiency, sustainable materials, and advanced electrical insulation solutions.

Cenvar’s Vision: Empowering Global Industries with Reliable Solutions

Since our debut in ELECRAMA 2006, our mission has been clear: To be the most trusted manufacturer and global supplier of insulating varnishes, enamelled winding wires, epoxy encapsulation systems, impregnating resins, and wire enamels for industries where reliability is non-negotiable.

Our solutions are engineered for industries including:

- Transformers and Power Equipment

- Electric Motors and Generators

- Electric Vehicles (EV)

- Renewable Energy Systems

- Industrial Machinery

Our ELECRAMA 2025 Showcase: Full Range of Electrical Insulation & Conductor Solutions

Insulating Varnishes – The Backbone of Reliability

Our electrical insulating varnishes offer outstanding dielectric strength, thermal endurance, and mechanical integrity. Widely used in transformers, motors, and industrial equipment, these varnishes ensure long-lasting protection and performance.

Copper and Aluminium Winding Wires – Precision with Performance

Our enamelled copper and aluminium winding wires have been a flagship offering since 2006. With precision enameling and excellent conductivity, these wires are critical for high-efficiency motors, transformers, and EV powertrains.

- High thermal resistance

- Superior mechanical strength

- Smooth, defect-free enamel coating

These winding wires serve as the backbone of countless electrical systems worldwide.

Solventless Impregnating Resins – Sustainable and Strong

Our solventless impregnating resins attracted global attention for their eco-friendly, high-performance characteristics. They offer:

- Low VOC emissions

- Excellent mechanical reinforcement

- Superior thermal stability

Perfect for industries moving towards green manufacturing without compromising on quality.

Epoxy Potting & Encapsulation Systems – Maximum Protection

Our epoxy potting compounds and encapsulation systems safeguard sensitive components from moisture, dust, vibration, and thermal stress. Essential for:

- Electronics

- Automotive applications

- Industrial machinery

These epoxy encapsulation solutions are trusted for durability and protection in demanding environments.

Wire Enamels – Enabling Durability and Efficiency

Our advanced wire enamels offer exceptional adhesion, thermal endurance, and fast curing—ideal for modern, high-speed winding processes.

Compatible with both copper and aluminium wires, they ensure operational stability in demanding applications.

Building Global Connections at ELECRAMA 2025

Our pavilion was a center of vibrant discussions with:

- OEMs

- Procurement heads

- Engineers

- Global distributors

Businesses sought not just products but partnerships built on trust, consistency, and world-class manufacturing capabilities.

Cenvar’s commitment to global supply reliability, technical support, and sustainable solutions was a key focus.

Visitor Response: Trust, Curiosity, and Long-Term Commitments

Industry professionals who had witnessed our journey from ELECRAMA 2006 to 2025 shared their appreciation for our growth, technology advancements, and global presence.

Our focus on delivering premium winding wires, insulating varnishes, and sustainable resin systems was met with enthusiasm and deep technical engagement.

Beyond ELECRAMA: A Future-Driven Commitment

The momentum doesn’t stop here. With expanding manufacturing capacities, enhanced R\&D, and an unwavering focus on quality and global delivery, Cenvar continues to drive industries forward.

Our materials power:

- Electric mobility

- Smart grids

- Renewable energy solutions

- Industrial automation

Cenvar is committed to powering a sustainable, electrified future.

Conclusion: From 2006 to 2025 — A Legacy of Excellence in Electrical Solutions

Our journey from a promising exhibitor in ELECRAMA 2006 to a global leader in electrical insulation materials and winding wire manufacturing at ELECRAMA 2025 speaks of relentless growth, customer trust, and technological evolution.

As industries move towards smarter, more sustainable power solutions, Cenvar | Chetak Mfg remains a dependable partner—engineering materials that power the world.